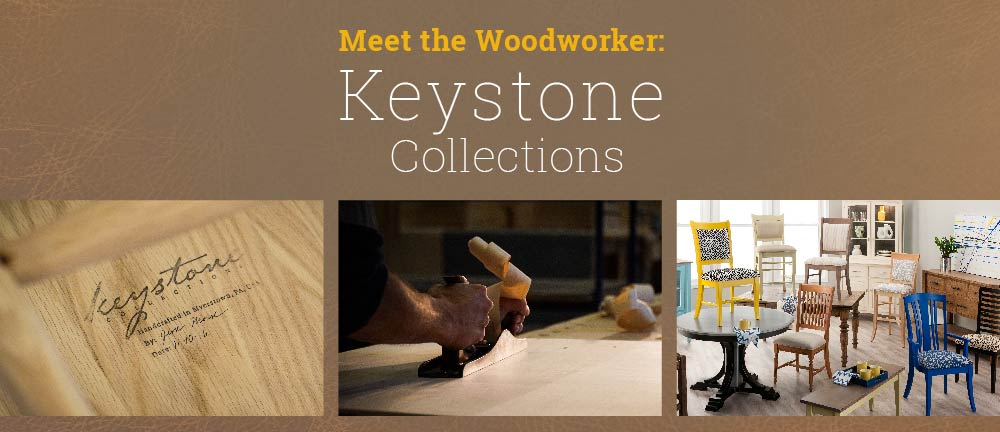

Meet the Woodworker: Keystone Collections

This blog post was originally written on May 26, 2017. In March of 2021, Keystone Collections was acquired by Canal Dover.

—

“One of the first projects Dad ever did was build heavy duty quilting frames for my mom,” Marvin Martin, co-owner of Keystone Collections, says with a grin. “Mom jokingly said it looked like it was built to hold an elephant.”

Seated in a chair on a late afternoon in one of the sprawling fields surrounding the Keystone Collections woodshop, Marvin continues with a hearty laugh, “But Dad was like, ‘if a job is worth doing, it’s worth doing right’.”

This phrase has become more than one of Marvin’s fathers’ sayings. It is a promise to Keystone’s customers and employees. It is also an extension of the faith that has helped to define the company’s core values.

—

Lovingly referred to simply as “Dad” in the company’s promotional materials, Glenn Martin opened the Keystone Collections workshop just outside of Myerstown, PA in 1986. Although he enjoyed wordworking, one of the main reasons he started the business was to ensure his four boys had work.

“Two of my brothers are somewhat handicapped, and he wanted to create an environment where they could work beneficially and [be] in a good [work place],” Marvin says.

Little did Dad know that 30 years later the company would grow from a small workshop to an over 55,000 sq. ft. facility sitting on over 20 acres, and employ over 50 people.

Keystone sign outside of the Myerstown, PA shop

Even with such growth, the company remains family owned and operated. Marvin and his brother James own the company, and their two brothers still work there, along with some of Marvin’s nephews. But, the Martins care so much about people, their other employees might as well be family, too.

Just ask Bryan Shive who joined the team a little over 10 years ago.

“It truly is like working for a family here,” says Bryan, who started out in the office and is now a sales executive. “We’ve shared stories, we share our lives together, we’ve shared tears together, and we strive together to create the very best furniture, the very best environment, and to provide the best service that we are possibly able to our customers.”

Marvin Martin and Bryan Shive

The Martins also value their team members input on everything from streamlining processes to furniture designs.

“Every week we request that each of our employees bring improvement ideas to management,” Bryan says.

This policy adds value to the work environment. It has also led to the implementation of innovative solutions that have added to the long-lasting quality Keystone furniture is known and loved for.

Bryan presented an idea that has come to be known the Martin Lock, a detail exclusive to the company. Martin Locks prevent the wedged tenons on chairs from becoming loose, adding to the their lifetime value.

Other details the made-to-order company includes standard are mortise and tenon construction on dining chairs, dovetailed drawers, and hidden steel ball-bearing drawer slides that fully extend and self-close.

“The [drawer slides] are rated for 100,000 cycles, and that means open and shut five times a day for 55 years, but we just say lifetime warranty,” Bryan explains. “We want to build all of our furniture in such a way that you don’t have any concerns about longevity.”

Dovetailed Drawers

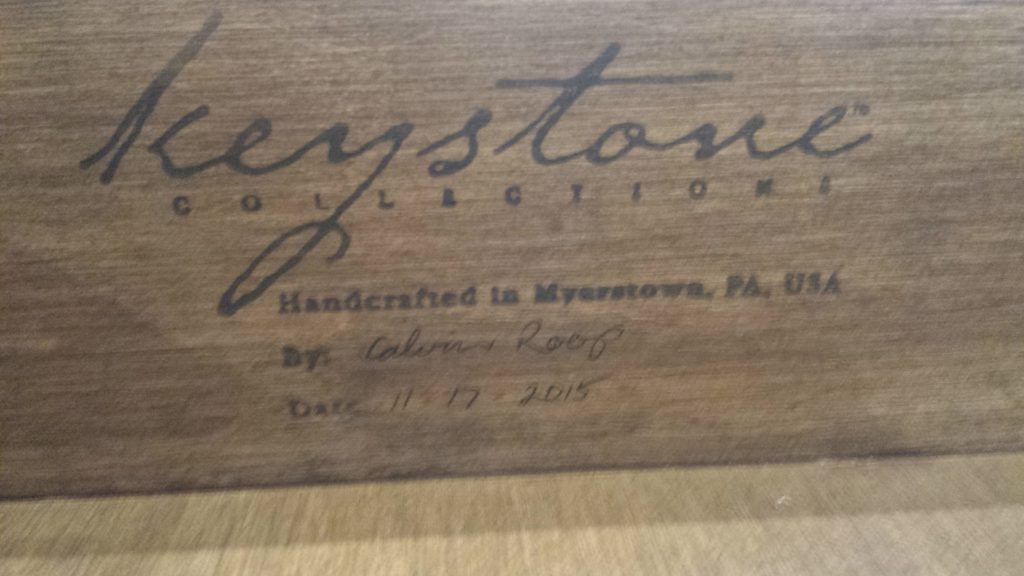

Another special detail that you will find standard on Keystone furniture is the signature of the person who built the piece and the date it was completed. This not only guarantees authenticity, but it is also an example of how the company stands behind its products.

Keystone drawer signed and dated by craftsman

—

Over 30 years ago, Dad built a prototype of a chair. He created it by hand on a lathe in his small shop in Myerstown. Today, thanks to his integrity and commitment to excellence, the shop isn’t so small anymore. The Martins family has expanded into tables, hutches, and bedroom furniture. Marvin, James, and the staff continue to carry on Dad’s legacy of crafting beautiful, impeccably constructed and inspected, custom-made, solid wood pieces built to be passed on to future generations.

Woodworker handplaning a tabletop to bring out the natural beauty of the wood

“This is our goal, from our family to yours, to allow you to experience the satisfaction of well-built, made in America furniture,” Marvin says.